Inside the Factory: Scout’s South Carolina Production Center Takes Shape

There’s a lot of talk in the EV world right now, but not many brands can point to real infrastructure rising out of the ground. Scout Motors can.

Just north of Columbia, South Carolina, the Scout Motors Production Center is turning plans into reality. What began with a groundbreaking in 2023 is quickly becoming a full-scale manufacturing hub. Once complete, the facility will produce more than 200,000 electric vehicles per year. Based on current progress, everything appears to be on schedule.

The Site: Scale and Strategy

The Blythewood site covers 1,100 acres and sits about 20 minutes northeast of Columbia with direct access to I-77. A dedicated rail connection is also under construction to support national vehicle distribution.

This is not a light assembly operation. The numbers speak for themselves:

- $2 billion investment

- 4,000 permanent jobs

- 40 vehicles per hour at full capacity

- More than 2.6 million square feet of production space across the body and assembly buildings

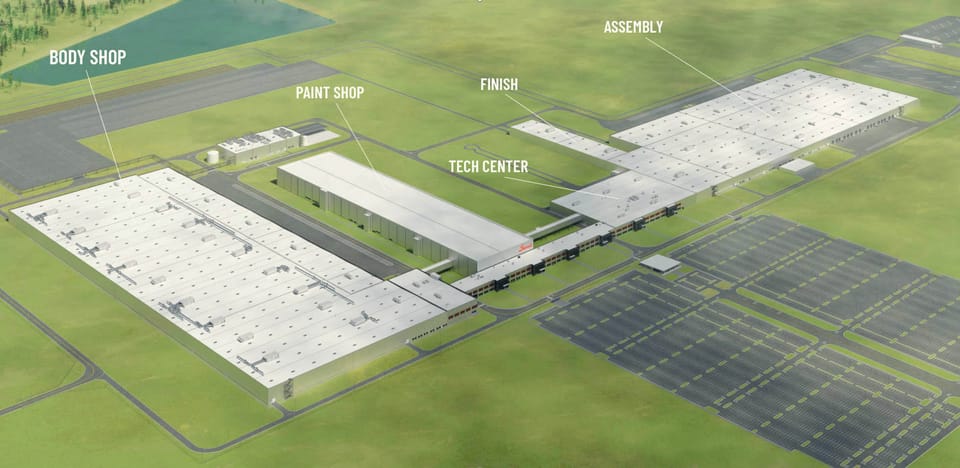

Scout is not just building vehicles. It is building a complete manufacturing ecosystem. The site will include a body shop, paint shop, final assembly building, technology center, and a training facility for employees.

Construction Progress: March 2025 Update

Scout recently shared its latest update on the site, including key progress on major structures:

- Assembly Building: Heavy steel installation is complete. Crews are working on roof decking and finishing materials. When finished, the building will span nearly 1.3 million square feet.

- Paint Shop: Work has moved indoors with equipment now being installed. Recent images show the first sections of interior machinery in place. The adjacent utilities building is also coming online.

- Body Shop: Steel framing is finished and exterior wall panels are being added. Roofing work continues across the structure, which will also exceed 1.3 million square feet once completed.

- Rail Connection: Scout has begun construction on a rail crossing over I-77. This line will connect the factory directly to national shipping routes, improving logistics once production begins.

Jobs and Workforce Development

According to Scout CEO Scott Keogh, this project is focused on long-term impact. The factory is expected to create 4,000 permanent positions. Roles will range from maintenance and logistics to high-tech equipment training.

“These are not gig, here-today-gone-tomorrow jobs,” Keogh said. “These are jobs with training, jobs in logistics and maintenance, and jobs in high-tech equipment. They’re built to last.”

An additional 5,000 to 5,500 jobs will come through Scout’s supplier network. About half of those suppliers are expected to operate within 200 miles of the plant, which will help reduce costs and strengthen regional connections.

Why This Matters

Scout is not operating behind the scenes or outsourcing its future. It is putting down roots and investing heavily in infrastructure, people, and long-term strategy.

With construction well underway and preorders already open, the return of Scout is no longer a distant idea. The buildings are up, the equipment is moving in, and the production line is coming into focus.

Scout is not just coming back. It is building momentum.